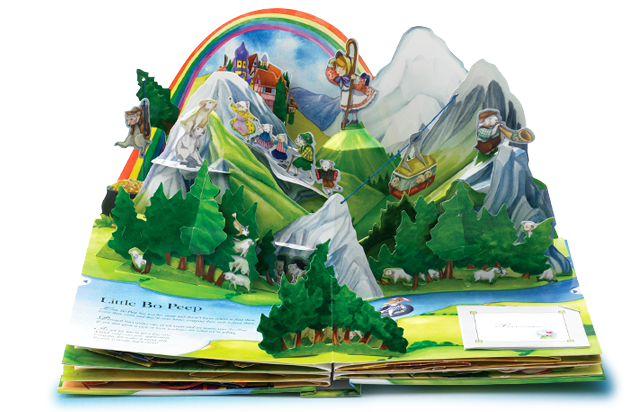

Take the Tour with Bo Peep

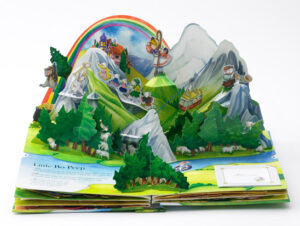

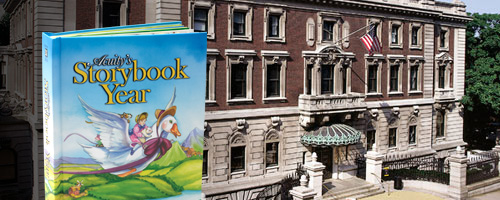

ACUITY’s Storybook Year Ensconced in Smithsonian

ACUITY's 2010 Annual Report is now permanent part of the rare books section of the Cooper-Hewitt collection at the Smithsonian Library.

ACUITY's 2010 Annual Report is now permanent part of the rare books section of the Cooper-Hewitt collection at the Smithsonian Library.

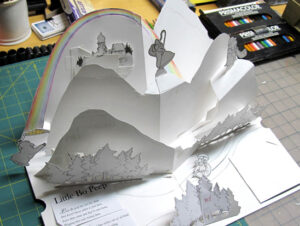

On April 18, 2011, Paper Engineer Andrew Baron presented a copy of ACUITY's Storybook Year to the Smithsonian along with a presentation on “The Birth of a Corporate Pop-up Book.” Baron, a key member of the team that produced our report, provided a behind-the-scenes look at the creative process behind our one-of-a-kind project.

“The Smithsonian refers to ACUITY's Storybook Year as ‘one of the most beautiful and compelling pop-up books designed to date,’” says Drew Foerster, the project's Art Director. “Given that popup art dates back hundreds of years, that is a remarkable testament to the quality of our project and the lasting value it is likely to have.”

An Annual Report That Really Pops

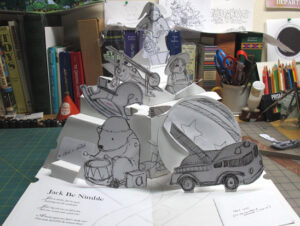

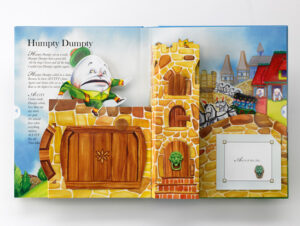

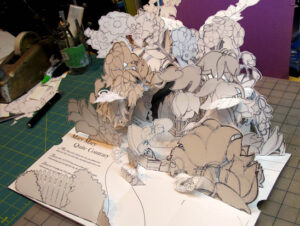

Across the entire globe, only a handful of professional Paper Engineers exist who have the skill to turn a two-dimensional illustration into a three-dimensional pop-up book the complexity of ACUITY’s 2010 Annual Report. Each spread is an intricate sculpture of cutouts, folds, tabs, and mechanisms that bring its drawings to life.

ACUITY partnered with one of the top paper engineers in the world: Andrew Baron, who has designed more than 20 books at his Popyrus Studio in Santa Fe, New Mexico. Andrew teamed up with renowned children’s book illustrator Aaron Boyd, who also has 20 book titles to his credit. Coordinating with Drew Foerster, Art Director at DuFour Advertising, the team helped our project take shape – literally – over the span of sixteen months, countless meetings and iterations, and 2,500 emails. The striking end result, ACUITY’s Storybook Year, was distributed to employees and agents at the end of February.

“The purpose of any advertising or marketing material, such as our Annual Report, is to grab somebody’s attention, stop them in their tracks, and have them dwell on it long enough to make a lasting impression,” says Ben Salzmann, President and CEO. “There’s nothing that does that like pop-up art because there’s an intrinsic surprise factor.”

Even though he has designed award-winning books and created eye-catching pop-up advertisements for corporate clients, such as Toyota and Sony, Andrew says that working on ACUITY’s project was a unique experience. “ACUITY’s Storybook Year is the most elaborate three-dimensional book that I’ve engineered in my career,” he says.

Aaron concurs. “This is by far the most fantastic and difficult project I’ve worked on,” he says. “Producing a pop-up book is three to four times the amount of work required for a regular book because it’s three-dimensional, but the end result is worth the effort.”

First-Hand Experience

If the number of Paper Engineers in the world is small, the number of publishers that can create a quality pop-up book is even smaller. “Pop-up books are one of the last handmade, mass-produced products in the world,” Andrew says. “Every step of the production process takes a team of extremely skilled people. Only a handful of specialty printers that have those resources exist, all of which are in the Far East.”

ACUITY chose Toppan Excel, recognized as the premier printer of pop-up books. Andrew and Drew spent several weeks on site in Guangzhou, China, during the critical printing, proofing, and assembly stages. “Because of the time difference and the language barrier, being able to be on site to work with the engineers gave us the opportunity to create a better product while making the production process more efficient. Ultimately it saved weeks of proofing via air mail,” Drew explains.

In late 2010, the assembled books were shipped to the U.S. All that remained was printing the “mini” booklets and financial statement page that detail our 2010 results, and that process was handled locally. “Working on this annual report was almost like creating two separate projects – first producing the actual pop-up book, then going through the whole process of creating a typical annual report to include within it,” says Bret Blizzard, Director - Corporate Communications.

But with the book in hand, the results are well worth the effort. “Everyone loves pop-up books,” says Wally Waldhart, Vice President - Sales and Communications. “ACUITY’s Storybook Year creates a huge ‘wow’ factor, and any time you can draw an audience in, you leave a lasting and positive impression about your company. This will live on and be passed from person to person – it will be a constant reminder that ACUITY stands out from the crowd.”